You are about to discover the simplicity and ease of building with ZEGO Insulated Concrete Forms step by step, a wall system technology that has been used successfully for over 50 years.

Nothing compares to ZEGO ICF’s for superior structural strength, versatility, installation and insulation benefits.

Conception

All projects start with a concept, an idea or a dream!

Once you have a clear understanding of what you are looking to build, measure room sizes and prepare a spread sheet of the rooms and sizes to work out your floor area

Your floor area measurement multiplied by the Building costs per m2 will give you a preliminary budget expectation to complete your project

If necessary, adjust your floor area to meet your budget

It is advisable to allow for an extra 10% into your budget for every 12 month period you are from commencing construction.

For example, if you are planning to start building next year and complete at the end of the year, you would allow for an extra 20% into the budge

Geotech Engineering

It is recommended to contract a Geotech Engineer to take a core sample at the location nominated by your project structural engineer of the building and or at the foundations rather than making an assumption on the soil conditions, as it might just save you thousands of dollars!

It is advisable to insist on this testing before purchasing the land!

A Geotech Engineer will give you a soil report based on the testing to pass onto your Structural Engineer.

The Structural Engineer will then design the footings / slab accordingly for these soil conditions

A ZEGO home built with 200 Series Forms weighs the same as a brick veneer home. Therefore,the slab is designed for the same loads and no articulation is required for H soil type upwards.

Your Plans, Elevation and Sections

With sketches and wish list in tow (your client brief), contract the services of an Architect / Building DesignerGenerally, an Architect/Designer will start off with conceptual drawings to scale (excluding full detail) for initial approval or adjustment

On approval of conceptual sketches, the drawings will be completed to Development Application requirements with specifications of inclusions

You may then direct your Architect/Designer to further complete drawings for Building Application Stage

On final completion of drawings, they may be certified by counsellor certified externally by a Building Certifier

Engineering drawings should be completed in conjunction with Architectural drawings as they need to be submitted together

NOTE: The Architect / Building Designer and the Structural Engineer will work together to full structural compliance without compromising on the Architect / Building Designer’s design

Engineering

The Structural Engineer will design the footings and slab to the requirements of the codes that govern them to resist the loads imposed by the building structure, the soil conditions, the wind loads of the area and other imposing influences

The Structural Engineer will work with the Architect / Building Designers to achieve the desired results

Structural Engineer and Architect / Building Designers are extremely important!

DO NOT skimp at this stage, as it’s the least expensive stage of an entire project and will provide you and the builder with the map for each stage of a project

Council Submission

All Councils are slightly different, so please click on the link below to choose your council.

You can then navigate to the planning / development department and in most cases you will be able to download hat is required for submission to your council and the fee involved.

Click here to choose your Local or Shire Council

Submission to council is quite simple, Architects, Building Designers and Builders do this on a regular basis on behalf of their clients.

Construction Certificate CC

Go to your Local Council’s web site and type in their search box “Construction Certificate CC”

Obtain your local council’s submission requirements

Large projects usually follow;

- Lodge the Development Application DA

- Once approved, you will be issued with your Construction Certificate CC, the CC may be issued by council or accredited certifier. The CC is confirmation that the building project complies with the DA consent, BCA and legislation. A CC will only be issued when the nominated licenced builder has lodged and paid for Home Warranty Insurance.

Survey

A surveyor is contracted to carry out the following items prior to commencement of any drawings

- When you are purchasing a block of land a surveyor would be contracted to check survey location to ensure you are purchasing the correct plot of land

- You will require for the Architect / Building Designer a Contour map of your land. A Contour map will provide you with Relative Levels (RL’s) to usually above mean sea level. This Contour map allows the Architect / Building Designer to position the home or project in a position and to allow for cut and fill requirements for excavation of the site alleviating excessive removal or supply of soil to the site, hence minimising the cost of the excavation process

- They will mark out the boundaries to exact or offset

- For larger sites, it’s advisable to setout to the XY grid lines A to Z and 1,2,3,4,5, etc

Excavation

Excavation of a site is carried out by

- Marking out the slab on the ground using the surveyors offset marks

- Carry out the bulk excavation work with the appropriate sized machine

- Mark out any Drainage/Sewer trenches as required

- Mark out any detailed excavation and carry out with an appropriate sized machine

- Fine tune or final trim by hand excavation

Concrete Footings

Concrete footings stepped and level

When building off strip footings, any steps are recommended/preferred to be in levels of 300mm ie 300-600-900-1200 etc

If you are using ZEGO Wall props, allow a 200mm clearance area to one side of the wall, so the wall props can be bolted down

Concrete Slab

Concrete slabs are engineered based on the load to be applied to the slab and the soil type

Guide to Residential Floors by the CCAA

Slab design for ZEGO 200 Series Forms weigh the same as a Brick veneer wall, so slab design is the same as for brick veneer and no articulation joints are required for H type soils and better. HD Type soil and mine subsidence areas are designed with articulation and approved mine subsidence drawings are available by request

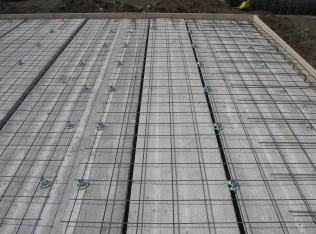

Starter Bars

It is preferred that you mark out your window, door openings and intersecting walls on your slab formwork edge board

Windows and doors should be marked out as per your window and door schedule (NOT AS MARKED ON YOUR DRAWINGS) The reason is that Architectural drawings are usually nominal and not exact! It is advisable to get a copy of your window and door schedule from your window and door manufacturer. Check the sizes are or are not inclusive of timber revels, as reveals usually add 2 x 20mm =40mm to the opening size

Starter bars are typically located in

- All corners

- All intersections

- 100mm either side of door and window openings

- At the appropriate maximum centres to suit the windload of the area

- At all vertical bars maximum 2 per core

- Protrude minimum 300mm out of the footing or slab

- Tie them into the slab or footing or lower them into the wet concrete precisely

- Centre of the wall eg 200 Series ZEGO forms are 190mm wide so the bar will be 95mm to the centre from the edge of the slab

Starter bars for retaining wall

- Centre to centre as nominated on the Engineering drawings

- Protrude minimum of 600mm out of the footing or slab

- Retaining wall starter bars must be cast in

Missing starter bars, wrongly located Starter Bars or for those who prefer to drill them

- Drill a hole 4mm wider than the bar size eg N12 starter bar drill a 16mm hole

- Depth of hole 125mm minimum

- Blow and brush the hole out

- If there is more than one bar to be drilled, then drill them all first

- Mix up a half cup of ZEGO two part epoxy

- Pour an appropriate amount into the hole and lower the starter bar into the hole so that the epoxy just comes out of the hole, top up hole if required NOTE: Be careful of your skin and eyes when using epoxy

- NOTE: Starter bars for retaining walls must be cast in

Once you have poured the footings or slab

- Before you remove the edge boards, use a roofing square and scratch a line back onto the slab from the window and door setout

Damp Proof Course DPC and Flashings

A liquid damp proof course is installed on the slab or footing directly under the ZEGO walls

It is painted up the starter bars 100mm and the width is the same as the width of the ZEGO wall

When you have started the excavation of your slab or footing, contact your ZEGO Project Manager by calling Local Call 1300 13 9346 or via e-mail:

The damp proof course is easy to install and should be completed prior to laying of the forms

Waterproofing

As a builder, owner, architect or engineer, waterproofing is the most important requirement.

You wouldn’t put bricks, blocks, or a timber frame in position and expect it to be waterproof.

Likewise with Insulated Concrete Forms.

The waterproof barrier, either spray on liquid or sticky back sheet membranes with a protection board and/or cell drain acts as a cavity to drain the water down to your agricultural silt or sock wrapped drainage system. Covered with the appropriate drainage gravel and geotech fabric to again protect the drainage system from silt build up and to keep hydrostatic pressure of water off the wall.

A sub-surface drainage cell on the entire wall is also an effective vertical drain. It also protects the waterproofing from damage from the back fill.

Although, there are plastic formwork systems that claim to be a 100% waterproof, logic and common sense should be applied.

Some considerations are the structural longevity of your building in the long term due to corroded structural reinforcement and the ability to repair and mitigate water or damp ingress into your habitable basement where valuable heirlooms, photographs, or metal machinery is usually stored and not to mention your health!

ZEGO Assembly Commercial

Click to view Assembly Details

ZEGO Assembly Domestic

Assembly of the ZEGO Domestic system is very simple by following the 10 basic rules outlined below;

- Use closed end forms at corners, intersections, at door and window reveals and to close off a wall

- Lay the forms in a stretcher bond format with every odd course above each other and every even course above each other

- Install past door openings so as the reveals will be on grid for lintel to lock in

- Only install cut forms with a minimum of two ribs

- Use open end forms to form lintels and bond beams (ring beam top course)

- Cut out side of intersection down to rib level to allow reinforcement to pass around corner

- Cut out any end closers down to rib level to allow horizontal reinforcement to run (required on bond beams and retaining walls)

- ZEGO forms will automatically form a core at corners and door and window reveals for vertical reinforcement steel to be placed

- When working to the mm you can cut forms above and below window or door openings and simply foam joint

- Wall Brace Scaffolding is placed in the corners, 100mm either side of door and window openings and at no more than 1800mm centre to centre. Tiewall to Wall Brace Scaffolding every 2 courses

Wall Brace Scaffold Trestle Installation and Awareness Guide

The Wall Brace Scaffold Trestle is a patented wall alignment system. It is an integral part of the installation of the ZEGO wall system

Wall Brace Scaffold Trestles are positioned

In the corners

100mm either side of door and window openings

and at no more than 1800mm centre to centre ( as this is the legal span for scaffold planks )

Adjusted plumb

Tie wall to Wall Brace Scaffold Trestle every 2 courses (Read more…)

Concrete Process

Firstly, ensure your concrete pump has a 50mm rubber hose. Same type used for filling block masonry walls.

A 50mm hose can be closed off simply and handled easily

Secondly, your concrete pump should be able to reach to the furthest corners from one location.

There should be enough room behind for the Concrete agitator to discharge safely into the concrete pumps hopper.

Also allow enough room for the outriggers of the concrete pump to bear on solid ground

Concrete as specified by the Project Engineer.

ZEGO recommend 32mpa 10mm aggregate max 180mm slump.

When pumping concrete into the ZEGO walls, please follow the OH &Safety guidelines below;

- First pass of concrete one course level = 300mm NOTE: Do not pour over lintels!

- Second pass of concrete no more than 900mm above the last level NOTE: If it has been less than one hour from the last pass you should not pour any more than 300mm above the first pass

- Third pass of concrete same as above

- Fourth pass of concrete same as above

- Pour the lintel in one pass followed by the bond beam level

- Your last pass of concrete is best to be only 300mm so that the concrete does not sink

- Level off for top plate bearing and top up with trowel and bucket and insert holding down bolts at appropriate centres

- If you are setting up for a slab then level off and insert starter bars for slab

Click here to see concrete pour rates– NOTE always start your concrete pour at the start of the day i.e. 6:30am-7:00am

Suspended Concrete, Timber and Steel Floor Systems

Guide to Residential Floors by the CCAA

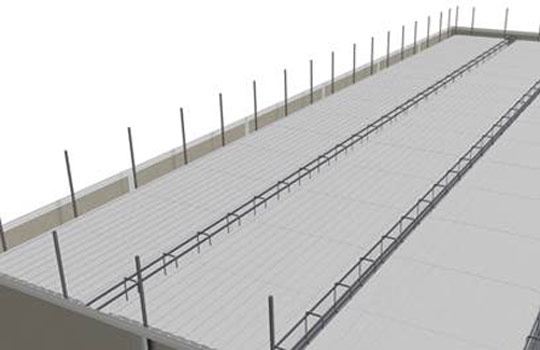

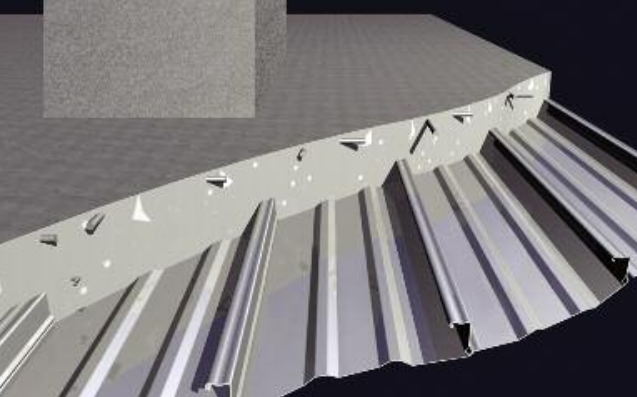

ZlabFORM

Our ZEGO ZlabFORM is our newly introduced integrated and insulated, reinforced concrete suspended flooring system

- Provides additional spans due to integrated connection of the reinforced concrete wall

- Can be incorporated onto any load bearing walls

- Fire Rated

- Insulated

- Lightweight

- No blocking required

- No Cranage required

- Recess your Services

Hydronic Flooring

Top Plate Setup

Use 10mm galvanised cup head bolts (length = top plate thickness + 15mm + length down to below top bond beam steel)

Insert it through an off cut of foam 45mm = Top plate thickness

This foam sits on top of the ZEGO wall and stops the bolt from sinking into the wet concrete and also keeps it centred and protects the thread

The next day, simply place the top plate over the bolts and hit with a hammer, then drill the timber where the marks are and bolt the top plate down. If you have leveled the concrete smoothly, tighten the bolts. If required, you can pack or shim the top plate level by using a string line

Roofing

Once the top plate is installed, mark out the ceiling joists and rafters or trusses and install

Eaves are installed as normal

If you plan to have exposed eaves, allow for the external ZEGO Form to finish at the top of the rafters

Roofing companies include Supplier Sterland Roofing & Cladding

Window and Door Frames

Firstly, it does not make sense to build an energy efficient building, then remove the foam insulation on the reveals when installing window and door frames!

Or to use metal frames that conduct heat in and out of your building.

Installation of Window and Door Frames

- The opening should be approximately 10mm larger around all the window or door frames

- Leave the foam in place and foam in using ZEGO window and door foam

- Wedge the frame square and plumb in the opening

- Make sure that any reveals are 15mm inside the room. This is to allow for the 10mm plasterboard and the 5mm air gap where the cornice cement is

- If you are rendering internally then the reveals are 10mm inside the room.

- 10mm is the thickness of the internal render.

- With sliding windows and doors open the slider a little so that you can rack the frame to have the slider and frame meet parallel

- Now tack the frame in place in the corners and at 600mm maximum centres using ZEGO window and door foam (Dries in approx one hour)

- Proceed with installation of other frames in the building for approx one hour

- Return to the first frame, check it is still square, in wind and plumb

- If all OK, remove the wedges

- Starting at the top of the window frame, spray ZEGO window and door foam in a continuous motion around the entire perimeter of the frame

- Allow to dry and proceed with the other frames in the building for approx one hour

- Repeat the full seal around the outside of the frame

- Cut the excess foam off using a razor blade at the stage of rendering the walls or installing plasterboard

NOTE

- Do not seal both sides at once, or foam will get all over the frame and you will use more foam than necessary

- The foam seal should be neat

- Do not trim off any excess foam until you are installing the render or the plasterboard

Roller Shutter Housings

Features and Benefits

- Roller shutters are seen as deterrent to intruders. Providing obvious protection against Burglary & Vandalism by preventing easy access through open windows.

- Creates difficulty for forced entry with or without tools.

- Insulating against both Heat and Cold

- Roller shutters prevent the Summer heat radiating through windows as well as preventing heat escaping during Winter months.

- $ave on Heating and Cooling costs all year round!

- Reduces your energy cost as well as the damaging effects on our Environment.

- Computer modelling through the University of NSW. Heating & Cooling (Ref Info Bulletin 026) has shown between 25 – 40% Energy Saving on residential properties and up to 59% on residential units.

- Average home per year $1,000 for heat and cool represents up to $400 per year saving!

- Roller shutters are operated from inside your home therefore no having to go outside in the middle of a storm or an unsafe scenario.

- Choice of ODS, manual or electric controls.

- Fully automated electronic controls are also available.

- A significant reduction in noise level is achieved whether it be busy traffic, neighbors or barking dogs.

- Great benefits for shift workers and young children needing to sleep.

- Close off your home completely to outsiders or create a controlled outlook with partially opened slats.

- This allows you the ability to out whilst still having privacy from the outside of the home.

- “Filtered light” is available at soft comfortable levels by simply partially opening the shutter. This will also create air flow allowing your home to “breathe” in your absence. Ideal for evaporative a/c systems.

- Ideal for coastal areas, Wind, Rain, Debris, Hail, are no problem for a roller shutter.

- Windows are secure so you sleep soundly through the worst storms.

- Do not rattle in strong winds.

- Protect leaking windows.

- Also advantageous for cyclone affected areas.

- Prevent the broken window and spot fires that so often destroy family homes during a bush fire.

- Roller Shutters create a barrier to stop burning debris from entering your home.

- Simulated bushfire exposure tests carried out by the CSIRO (Report BCE Doc.02/160, June 2002) have shown OZ roll shutters provide improved levels of protection against bushfires.

- Prevent sunlight fading your carpet, paintings and soft furnishings.

- Window frames and interior furnishings will last longer with roller shutters.

- “Protect your property from the harsh Australian climate”.

- Clear operation parallel to the window and wall prevents interference with exterior paths and walkways.

- Ideal for larger homes built on smaller blocks

- Stylish Design

- Unobtrusive

- Blends with any architectural style.

- Wide range of colours to choose from.

- OZ Roll is the largest roller shutter manufacturer in Australia and we use high quality materials and coatings this includes pre-coated ABR’s and Dura Coat 5000.

- A better product is nearly always better value for money.

- A product that that has the ability to be able to pay for itself, due to cost saving on energy, not to mention overall peace of mind.

Drive System

- An affordable motorised control system that is battery operated and therfore not reliant on mains power.

- This unique product is visually appealing with operation at the touch of a button and no unsightly straps or cords.

Drive System Components

- Contoller

- Wallplate

- Mechanism 10

- Axle Adaptor

OZ Roll Drive System Features & Benefits

- Charging is both simple and convenient

- Low Voltage operation (no electrician required)

- Direct replacement for existing battery back up systems

- Lifting capacity of 20kg – equal to the typical 10N tubular motor

- Nominal speed of 16 rpm

- No minimum width restrictions

- LED indicators showing operational & charging characteristics

- Automatic limit settings – no adjustment required

- No exposed tape as compared to winder and strap

- Multiple shutters can be operated by a single controller

- Operation not reliant upon mains power.

- Limited wall space is required

- Simple operation for the whole family

Services

Manufacture and Assembly

Our manufacturing facility is supported by state of the art machinery, including machines that have been specifically designed to suit our range of products. Our fully trained and qualified operators conduct comprehensive maintenance programs to ensure down time is kept to a minimum and quality is of the highest standard.

As well as being able to offer individual materials and components ZEGO also has the ability to supply fully assembled custom-made roller shutters. Due to our efficient and productive assembly operation, you can be assured of a quick and efficient turnaround time.

Supply and Distribution

Our despatch department ensures that all orders are carefully packaged to ensure complete protection throughout the delivery process. Our dedicated distribution team has extensive knowledge of all the transport options and can arrange delivery on time, every time.

Ordering

In order to simplify and standardise the process for ordering Materials and Assembled Shutters, ZEGO has developed a simple and accurate ordering program that is made available to our valued customers.

Click here to email your window schedule for a free quote

Click here to fill inorder spreadsheet

Note:

- Final sizes can be confirmed for manufacturing once the openings in the ZEGO walls are confirmed.

- Side guide channels available for Domestic 53mm x 22mmand Commercial Fire form 69mm x 23mm

- Super Shutter Series Lock guides are 68mm x 25mm

Wiring, Plumbing, Data Services

Firstly, mark on the wall where services are to be installed

Chase the wall using a hot knife, electric router or circular saw

If using an electric router or circular saw, set the depth to just miss the concrete

Only cut wide enough for the pipe or conduit to fit

If you cut more than necessary, simply use ZEGO Spray foam to fill it back in

Services through wall for Hot Water and gas connection will be sealed to the base coat of acrylic render with polyurethane sealant, also then seal the trim plate to the wall also for a neat professional finish.

For alpine areas where pipes are insulated/lagged the use of a decktight can also be used to seal of weather entry.

Services through wall for Hot Water and gas connection will be sealed to the base coat of acrylic render with polyurethane sealant, also then seal the trim plate to the wall also for a neat professional finish.

For alpine areas where pipes are insulated/lagged the use of a decktight can also be used to seal of weather entry.  Plumbing, electrical and data is easily chased and precisely terminated into the ZEGO foam causing no structural damage to the reinforced concrete core.

Clipping back water pipes to the concrete face eliminates water hammer issues.

Please note the professionalism and experience of the plumber and builder with the additional timber frame noggins to secure the water pipes against water hammer noise.

Plumbing, electrical and data is easily chased and precisely terminated into the ZEGO foam causing no structural damage to the reinforced concrete core.

Clipping back water pipes to the concrete face eliminates water hammer issues.

Please note the professionalism and experience of the plumber and builder with the additional timber frame noggins to secure the water pipes against water hammer noise. External Finishes

- External Finishes include but not limited to are Acrylic textured or smooth coloured render all 8mm+2mm for Acrylic base and top coat renders, Stone – Stack stone, tiles, Alucabond, Batten and weatherboard, MiniOrb, ColorBond

- Internal Finishes include but not limited to are plasterboard allow 10mm or 13mm plus 5mm cornice cement, 8mm+1mm for Acrylic base and setcoat coat renders or stone or tile thickness

Render

Render is the most commonly used finish

- Firstly, brush down the surface to remove any debris

- Trowel on 4mm of base coat acrylic render (render to comply with CA26 Compliance)

- Roll out the reinforcement mesh for the render and trowel onto the surface

- Do not staple the mesh to the wall

- Overlap the slabs edge by 50mm minimum

- Cut 45 degrees from the corner of the window openings

- Measure the reveal back to the windows, then measure, cut the mesh and fold back onto the reveals

- Ensure you reinforce the corners with additional reinforcement mesh

- Trowel on another 4mm of base coat

- On completion, an 8mm base coat with reinforcement mesh in the centre for impact resistance

Render companies in no particular order include

- Render Texture (rtp)

- Supacoat http://supacoat.com.au/

- Rockcote http://rockcote.com.au/

- Unitex http://www.unitex.com.au/

- MAC http://www.melbacrylic.com.au/

- Astec http://www.astecpaints.com.au

- Acryloc http://acryloc.com.au/documents/acryloc-system-pack-wallcote-1871755024-2014-09-10.pdf

- STO http://www.sto.co.nz/

- RSA http://www.rendersystemsaustralia.com.au/

- James Hardie http://www.jameshardie.com.au/

- Dulux AcraTex http://www.dulux.com.au/specifier/our-brands/dulux-acratex

Sills and Moldings

- Glue and fix moldings as required

- Use only molding with a minimum 10mm render finish or epoxy finish.NOTE: Never use painted molding

- Seal the perimeter with SIKA Flex polyurethane sealant and wipe with wet finger to form a cove or fillet between wall and molding

- Apply the finish colour coat

Apply the final finish towards the end of the project

- Second coat finish is the textured colour finish

- Applied 2-3mm thick depending on the stone size

- By using a foam, sponge or fibre glass trowel you can achieve differing finishes

Paint finish

- Membrane paint applied as per manufacturers specification

Timber Weather Boards

- Install battens on wall and fix to plastic interconnects ( FireFORM System )

- Install battens on wall and fix back to concrete ( HomeFORM System & FireFORM System)

- You can also recess timber battens into the wall

- Install sarking or moisture barrier

- Fix weatherboards and paint or stain

Stone Facing

- Apply waterproofing or base coat of render with reinforcement mesh

- Use external adhesive as specified by the stone supplier

- Adhere to wall

- Use timber dowels to form joints and perpends

- When dry, remove dowels and fill joints with appropriate grout

- Seal surface as required

Plasterboard

- Install plasterboard by placing a dab of cornice cement at 300mm centres on the wall

- Place some small packers against the floor and wall junction10mm typically

- Place the sheet vertically or horizontally against the wall on top of the packers

- Use a straight edge and tap the plasterboard which will squash the cornice cement out like a pancake and will push the cornice cement into the dovetailed grooves of the ZEGO Form

- The cornice cement when dry will mechanically lock to the ZEGO Form

- Cornice cement is recommended as it dries more quickly.However, stud adhesive can also be used

- Typically, the gap behind the plasterboard would be approximately 5mm

Benefits

- No screw holes to set and sand

- When painted, the walls look better as you do not see any screw hole patches

- Fast and simple

- The cornice cement takes up any tolerances ensuring the plasterboard lies flat and straight

Tips

- During the height of summer or in hotter climates, mix some GP 100 with the cornice cement to slow down the setting process

- Mix to a consistency similar to toothpaste